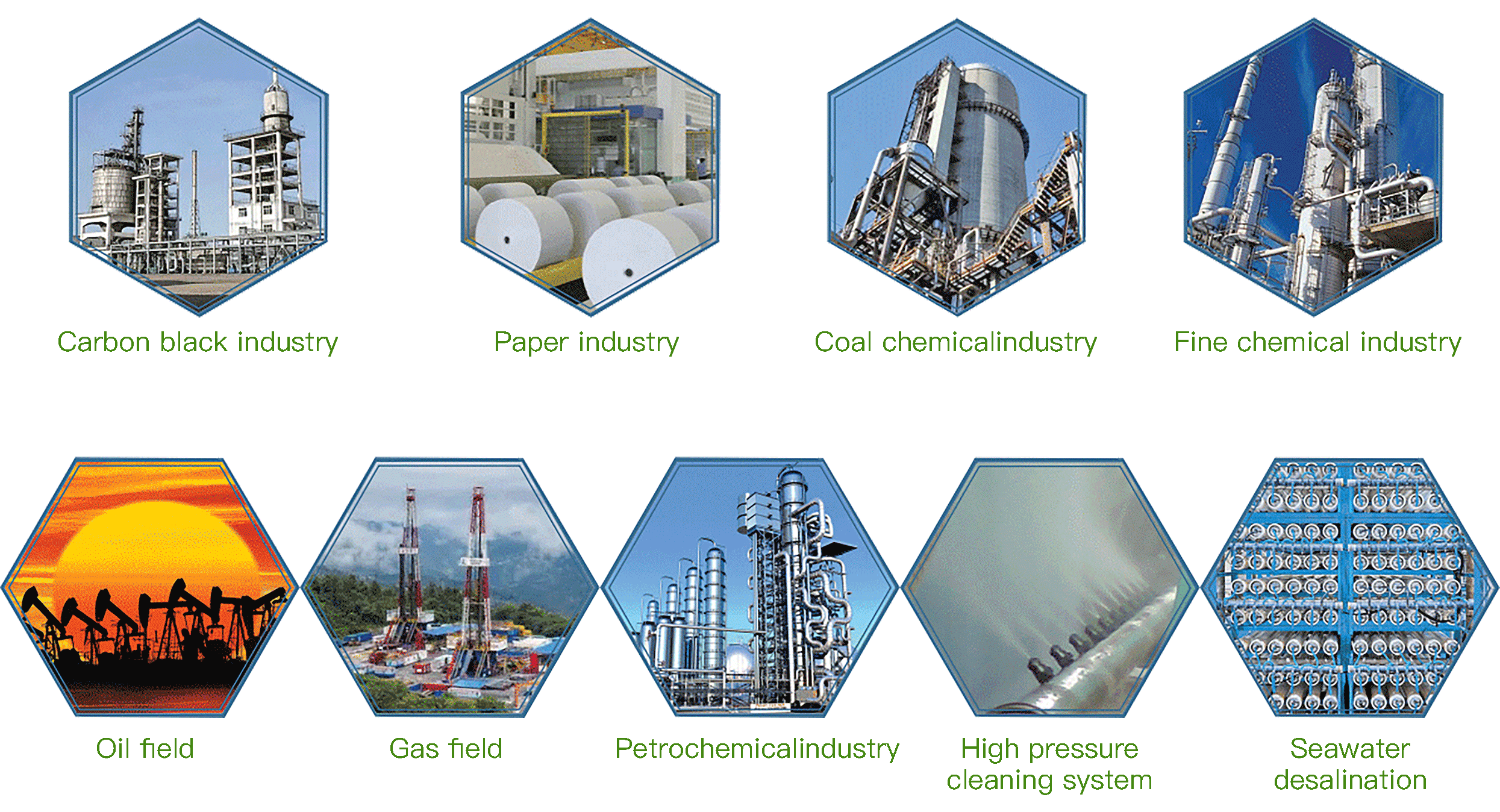

Application-Field

Main application areas of rotary jet pump

It is mainly used for conveying clean liquid or liquid containing solid particles (for conveying liquid containing solid particles, the receiving tube must use wear-resistant materials). Rotary jet pump is widely used in petroleum, chemical industry, fertilizer, metallurgy, mining, carbon black, paper and other industries, is the ideal replacement of high-speed centrifugal pump, high-pressure multistage centrifugal pump and some positive displacement pump.

① Carbon black industry(Outline)

Feedstock for carbon black production companies feeding pump transmission characteristics of small flow and high pressure, and carbon black feedstock oil with viscosity, contains bitumen particles, easy to condense at low temperature characteristics. Previous common plunger pumps, screw pumps, multistage centrifugal pumps are easy to wear and leakage shortcomings, cannot be used long-term stability and other issues. Now with the increasing output of carbon black production line, for raw materials and oil pump delivery pressure and with increasing,the stagnation booster energy-saving pump became a manufacturer of carbon black feedstock delivery of standard products.

Traditional fuel oil transfer gear pump, easy to leak, frequent problems such as damaged replacement equipment, energy-saving pump replacement for fuel oil transfer gear pump can be long-term and stable operation.

② Paper-industry(Outline)

The stagnation booster energy-saving pump used in paper-making factories and high pressure waterwashing machine net, felt surface cover with a good cleaning effect, Rinse thoroughly addresses the current paperpump pressure drops and so on. The energy-saving pump is currently in a foreign country has become standardequipment of pulp and paper industrial high pressure cleaning equipment,in favor of more and more paperfactories in the country.

③ Gas-field/oil-field(Outline)

The stagnation booster energy-saving pump has advantages of small flow, high pressure head,without leakage, widely used in petroleum, petrochemical and other fields each process, as process pump. Energ y-saving pump combines multistage centrifugal pumps and positive displacement pumps advantages, but also to make up the shortcomings and deficiencies of the two types of pumps in the structure, therefore have a high reliability, long-term maintenance-free features.

RFM using high quality corrosion resistant materials for mine conveyor particle content is not more than 1.5% with corrosive mine water (particle size less than 0.5 mm), according to the different etching conditions used different materials

④ petrochemical-industry(Outline)

The stagnation booster energy-saving pump as the chemical process pumps are widely used in chemicaprocesses, due to having a low flow, high head, no leaks, etc. Energy-saving pump combines multistage centrifugapumps and positive displacement pumps advantages, at the same time also makes up for the shortcomings and theinsufficiency of the two kinds of pump in structure.