High-Pressure Pitot Tube Pumps & Replacement Parts

100% Interchangeable with Roto-Jet® Models. API 610 Compliant Standards.

API 610 Compliant | 100% Interchangeable with Roto-Jet® | Low Flow, High

-

Max Head: Up to 1,500 m

-

Max Flow: Up to 100 m³/h

-

Design: Single-stage, Low-specific-speed

Product Overview

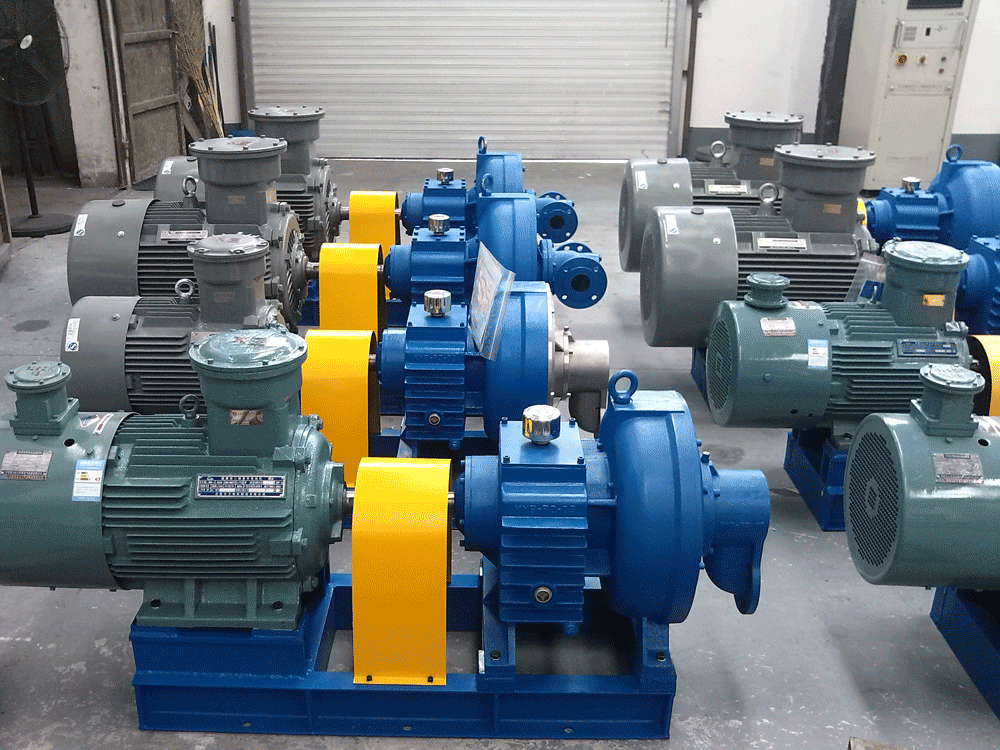

Pitot tube pump is an advanced high-pressure chemical pump developed by WeiMing Technology. Engineered as a single-stage, low-specific-speed pump, it is specifically designed for low-flow, high-head fluid transfer applications.

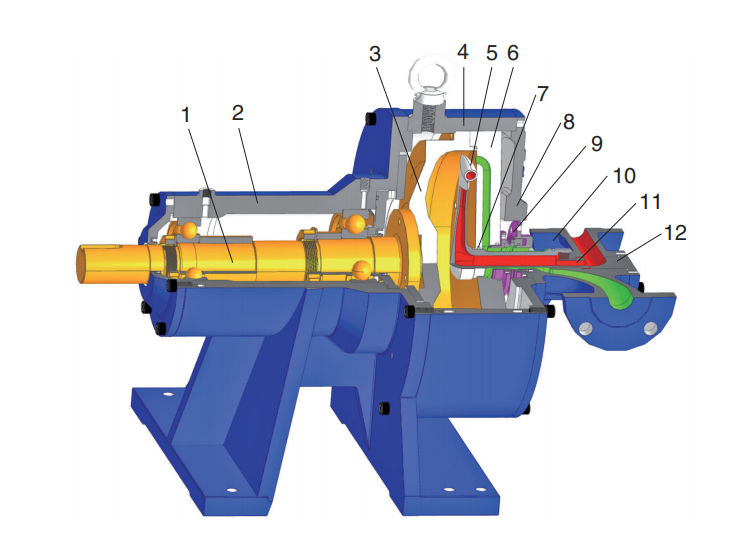

Working Principle: The total head generated by the pump is the sum of the static pressure head created by centrifugal force and the velocity head captured by the stationary pitot tube.

Key Advantages: Featuring the simplest construction in its class, the R-Series is both compact and highly reliable. It offers superior stability and a significantly longer service life compared to traditional high-pressure pumps.

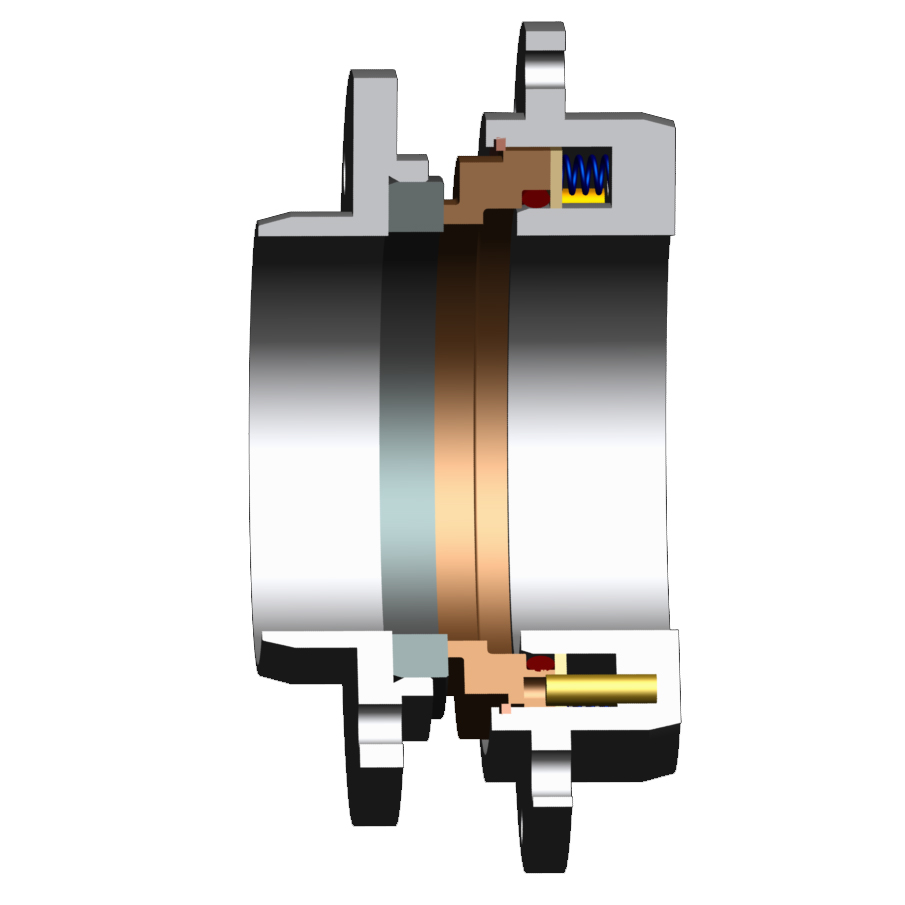

Patented mechanical seal

Core component: receiving tube

Main application

R series roto-iet pump is mainly used for pumping clean liquids or liouids containing solid particles.

Roto-Jetpumps are widely used in petroleum, chemical, fertilizer, metallurgy, mining, carbon black, paper and other industriesis the high-speed centrifugal pumps, high pressure multistage centrifugal pumps and partial displacement pump idealalternative.

Roto-jet pump has become the automotive industry drilling flushing system infusion pumps, carbon blackoroduction ine feed pump device of choice. and has become the field of chemical waste treatment plant deep. highpressure food processing CIP cleaning system, cleaning system and paper manufacturing plant industry standard highpressure cleaning equipment.

Operating data

1. Capacity:0~100m/h

2. Head:40~1050m

3. Speed:≤5015r/min

4. Suction Pressure:≤1.5MPa

5. Temperature up to:≤180C

6. The highest temperature: According to the conditions determined

7. Maximum power:≤250kw

8. Ways of changing speed: converter、gears、belts

Advantages and Benefits

◆ Single stage, low flow(0~100m3 /h), high pressure(100~1500m)

◆ At low speed (3000rpm) can achieve high head (up to 500 m).

◆ Medium adaptability, not sensitive to transmission medium. Conveying medium can be thick, can also be thin; It can be either corrosive or non-corrosive; Can be clean, can also be containing a small amount of impurities, containing a small amount of gas;High temperature (up to 230 degrees).

◆ Simple structure, small volume, less moving parts; Almost free maintenance, low maintenance cost, long service life.

◆ Inside the pump only has two basic working parts: a rotating rotor and a stationary receiving tube.

◆ The rotor adopts forging manufacturing techniques, after strict high-precision dynamic balance test, effectively guarantee the product more stable and reliable running.

◆ Seal reliability is strong, only in the low pressure pump inlet has a mechanical seal, solved the high pressure pump the prevalence of high pressure sealing problem.

◆ Has the advantage that the total head curve scope of work, at any point are all have stable hydraulic pressure output without pulsation.

◆ Anti-cavitation performance is good, can take a certain amount of gas to run, to avoid the liquid to cause the damage of the pump.

◆ Flow characteristic curve smoothing,and output liquid pressure without pulsation, very suitable for the requirements of a more balanced fluid production jobs.

◆ The pump does not generate an axial force, the axial force mainly from the inlet pressure.

◆ All seals are made of good reliability of imported products, mechanical seals for the balanced single mechanical seal.

◆ Performance of the adjustment can be through changing the rotating speed of pump and/or replacement of different size of the receiving tube.

◆ All the parts inside the pump chamber are easy installation and removal, including mechanical seals included, can be easily maintained.

◆ Efficiency compared with the high pressure multistage centrifugal pump, high-speed centrifugal pump high pressure pump is higher.

◆ Combines multistage centrifugal and positive displacement pumps advantages, while avoiding the two pumps in the

structure of the shortcomings.

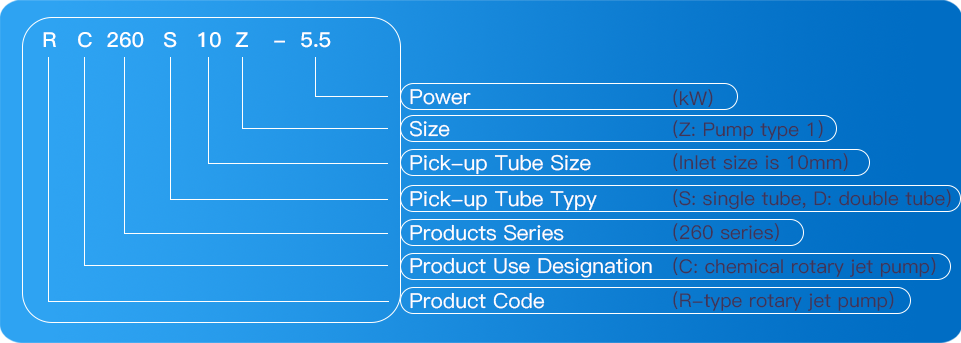

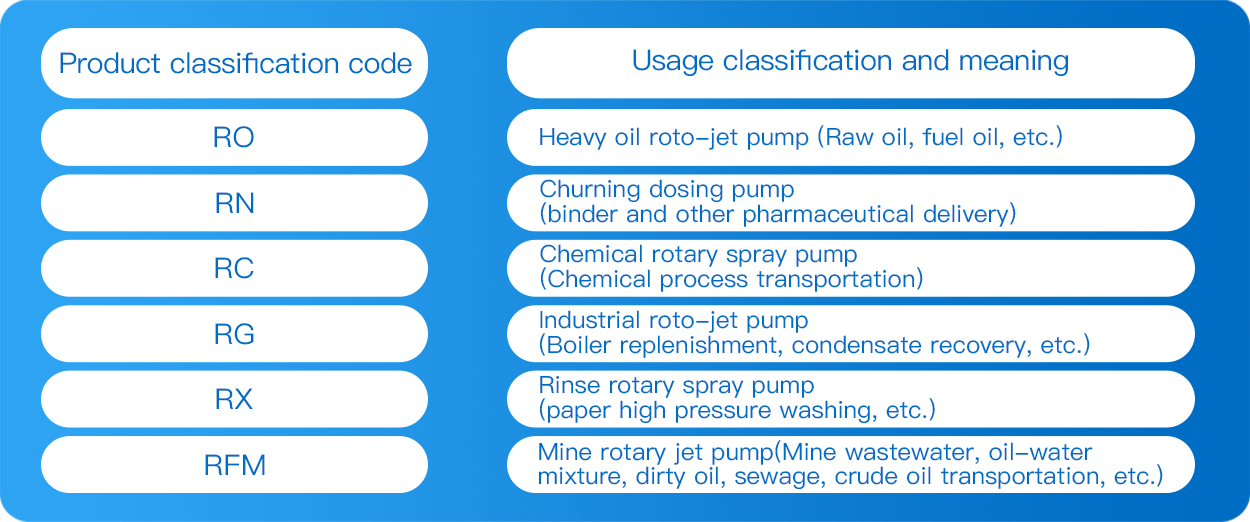

R series rotary jet pump product classification code and meaning

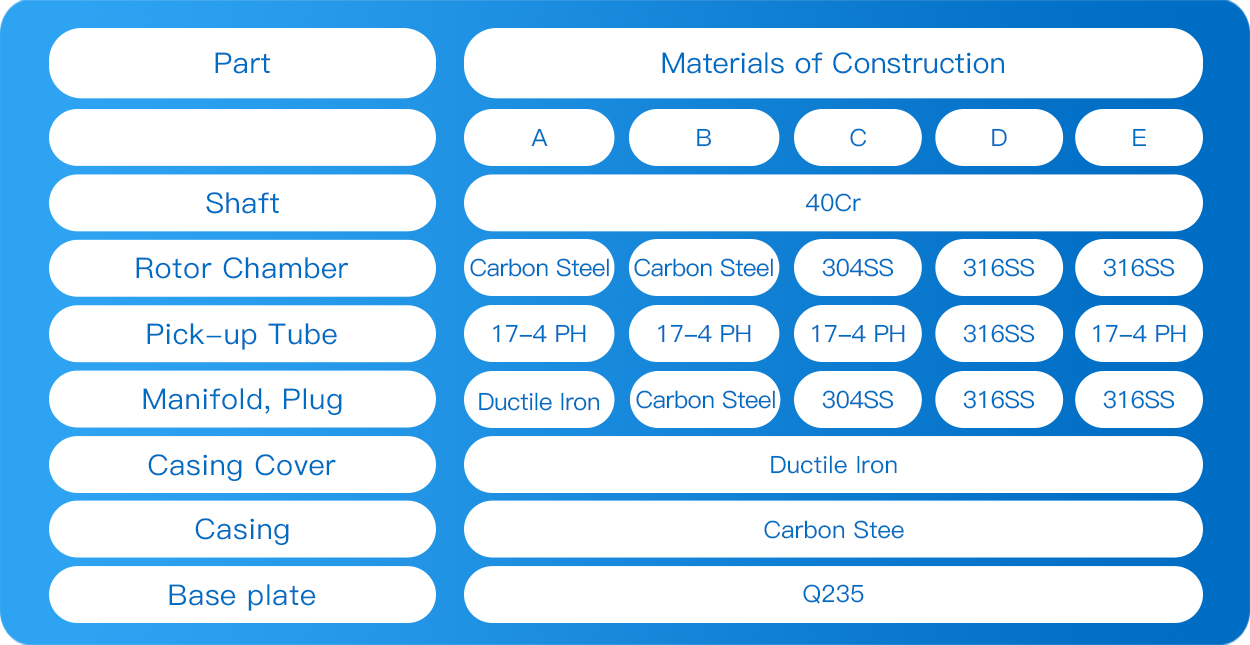

Materials Construction

Note: if you need other material products, please contact with the company.

Type Designation